After daily operation, excavators and their attachments require maintenance and upkeep. This document discusses the maintenance and upkeep of excavator attachments such as hydraulic breakers and auger drills from the perspective of on-site operation and technical maintenance. This is not only fundamental to mechanical preservation but also directly relates to the efficiency, safety, and service life of the equipment. Based on engineering machinery technology, combined with practical operating experience and industry practices, this document provides an introduction to the maintenance and upkeep of excavator attachments such as hydraulic breakers and auger drills, hoping to serve as a practical maintenance guide for industry professionals.

Hydraulic breakers are one of the most commonly used heavy-duty attachments for excavators. They use a hydraulic system to drive a piston to strike the chisel at high speed, generating impact force to break concrete, rocks, and other hard materials. These attachments have high working intensity and intense vibration, so daily maintenance is crucial.

1.1 Appearance and Connection Parts Inspection

After daily operation, it is essential to check for abnormal clearance between the chisel and the bushing (normal clearance ≤2mm) and observe for any hydraulic oil leakage. Tighten the bracket bolts and connecting pins, using a torque wrench to retighten them according to the manufacturer's manual (error ±5%) to prevent loosening due to impact loads.

1.2 Lubrication System Operation

Use NLGI 2 grade lithium-based grease, injecting 20–30 grams per time into the chisel guide bushing. Before greasing, the chisel must be vertically pressed into the ground to its limit position to prevent grease from entering the striking chamber and causing "black oil" contamination. Grease at least twice after daily operation; in high-dust environments (such as Chongqing mines), this should be shortened to once every 4 hours.

1.3 Hydraulic System Maintenance

Hydraulic oil replacement cycle: 500 hours under normal working conditions, 300 hours under harsh working conditions. The oil standard is ISO VG46, and the contamination level should be ≤NAS 8.

Return oil filter replacement: The first replacement is at 50 hours, and then mandatory replacement every 100–150 hours. Replacement is required if the pressure difference > 0.5 bar.

Oil temperature monitoring: The working temperature should be controlled at 50–75℃. If it exceeds 85℃, stop the machine immediately for cooling to prevent seal aging. 1.4 Key Prohibited Operations

❌ Do not operate the hammer without load, at an angle, or while suspending heavy objects.

❌ Do not use steel rods to pry rocks or as levers.

❌ Do not continuously strike at a single point for more than 60 seconds to prevent piston overheating and bushing wear.

1.5 Long-Term Storage Procedures

If the equipment is to be out of service for more than one month, especially in a humid environment, release the nitrogen from the upper cylinder, push the impact piston into the middle cylinder to prevent rust, and apply special anti-rust oil to exposed metal surfaces.

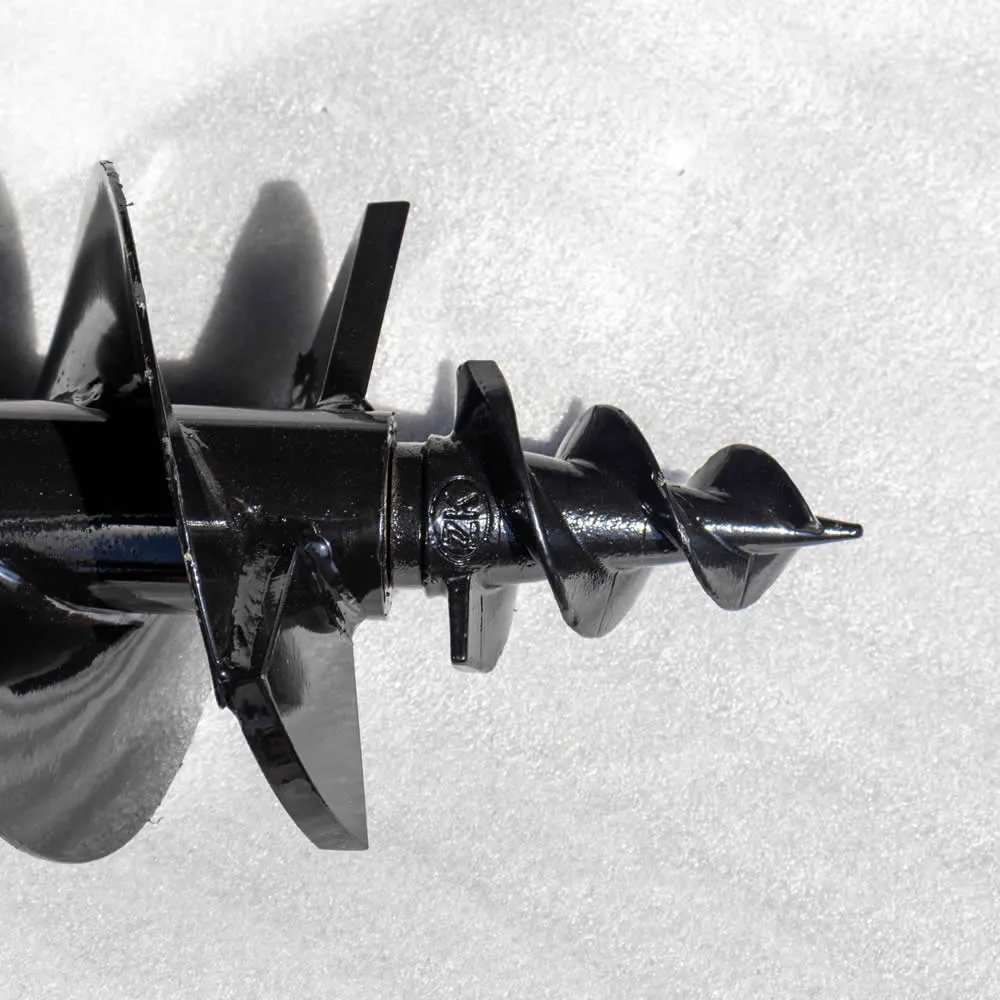

Auger attachments are commonly used for drilling, piling, and planting holes. They rely on hydraulic rotation to drive the auger bit into the ground. Unlike powerful impact breakers, augers emphasize continuous rotational load and torque management.

2.1 Drill Rod System Cleaning and Inspection

Immediately after operation, rinse the inner and outer walls of the drill rod, the spiral blades, and the chip removal groove with clean water to remove adhering soil and rock debris. It is strictly prohibited to operate in acidic, alkaline, or salt spray environments (such as chemical zones near Chongqing) without cleaning afterwards to prevent electrochemical corrosion.

2.2 Critical Wearable Parts Condition Assessment

Threads and Seals: Check if the male and female threads are worn or deformed, and if the O-rings are aged or cracked. Replace damaged parts immediately.

Shock Absorber Assembly: Replace if the rubber is aged or detached to prevent the drill rod from impacting the main unit during descent.

Spring Seat and Shock Absorber Spring: Check for breakage or deformation. Welding repairs are strictly prohibited; original factory replacement is required.

Keyway Burrs: After the first 50 hours of use, the drill rod must be pulled out, and the burrs on the keyway surface must be polished to prevent "rod jamming."

2.3 Lubrication and Rust Prevention

Daily check and add 0# lithium-based grease to the lifting device, rotary support, and power head turntable.

After daily operation, evenly apply anti-rust oil (benzotriazole-containing oil is recommended) to the outer surface of the drill rod, especially in environments with an average annual humidity >80% (such as Chongqing). Daily application is recommended and should not be skipped. 2.4 Storage Specifications

Drill rods must be fully extended and suspended vertically or laid flat on a dry wooden rack. They must not be piled on gravel or muddy ground.

For long-term storage, protective caps should be installed on both ends, and the rods should be stored in a well-ventilated, dry warehouse with humidity controlled below 60%.

|

project |

Normal working conditions |

Harsh working conditions |

Operating Standards |

|

Hydraulic oil change |

500 hours |

300 hours |

ISO VG46, contamination level ≤ NAS 8 |

|

Hydraulic filter replacement |

250 hours |

150 hours |

Pressure differential > 0.5 bar Requires mandatory replacement |

|

Grease filling |

Every 8 hours |

Every 4 hours |

NLGI Grade 2 lithium-based grease, inject until overflow. |

|

Rust prevention treatment frequency |

weekly |

daily |

Apply special rust-preventive oil immediately after the operation. |

|

Comprehensive disassembly and inspection cycle |

1000 hours |

600 hours |

Piston ultrasonic flaw detection: Drill pipe bending degree ≤ 0.5 mm/m |

4.1 Rust Prevention Measures

All exposed steel components (such as brackets, connecting flanges, and drill rod bodies) must be sprayed with a long-lasting rust inhibitor (such as 3M™ Scotchgard™ or equivalent domestic products) after each day's operation.

It is recommended to install silicone dust caps on hydraulic pipe joints and electrical plugs to prevent moisture intrusion.

The slewing bearing and travel motor bearings should be dehumidified weekly by blowing away accumulated water with compressed air.

4.2 Electrical System Protection

Check the battery terminals for oxidation, and apply petroleum jelly or special anti-corrosion paste monthly.

Place desiccant packs in the control cabinet; it is recommended to replace them every two weeks.

4.3 Storage Recommendations

Outdoor parking is strictly prohibited. The equipment should be stored indoors or covered with a waterproof tarpaulin, with the bottom raised at least 20 cm.

For long-term storage, drain the accumulated water from the hydraulic system, inject rust-inhibiting hydraulic oil, and start the equipment at low speed for 10 minutes to circulate the rust-inhibiting oil film.

Maintenance of excavator attachments should not be limited to the attachments themselves. The hydraulic system is the power source for hydraulic breakers and auger drills. Maintaining clean hydraulic oil, stable oil temperature, regular filter replacement, and undamaged hydraulic hoses on the excavator itself is fundamental to ensuring the long-term stable operation of the attachments.

Regular maintenance of attachments is a key step in reducing failures, improving work efficiency, and lowering lifetime costs. Establishing a detailed maintenance log, combining the manufacturer's periodic maintenance plan, system checks, and the operator's on-site observations, is a reflection of every maintenance engineer's professional competence.

Hydraulic breakers and auger drills, as "high-impact, high-wear" core attachments of excavators, have a lifespan that is 70% dependent on the quality of daily maintenance. In hot and humid environments, "frequent cleaning, timely lubrication, and strict rust prevention" are essential for extending equipment lifespan. We urge every maintenance engineer to incorporate this guideline into their daily work routine, ensuring that each maintenance task becomes a cornerstone of equipment safety and efficiency.