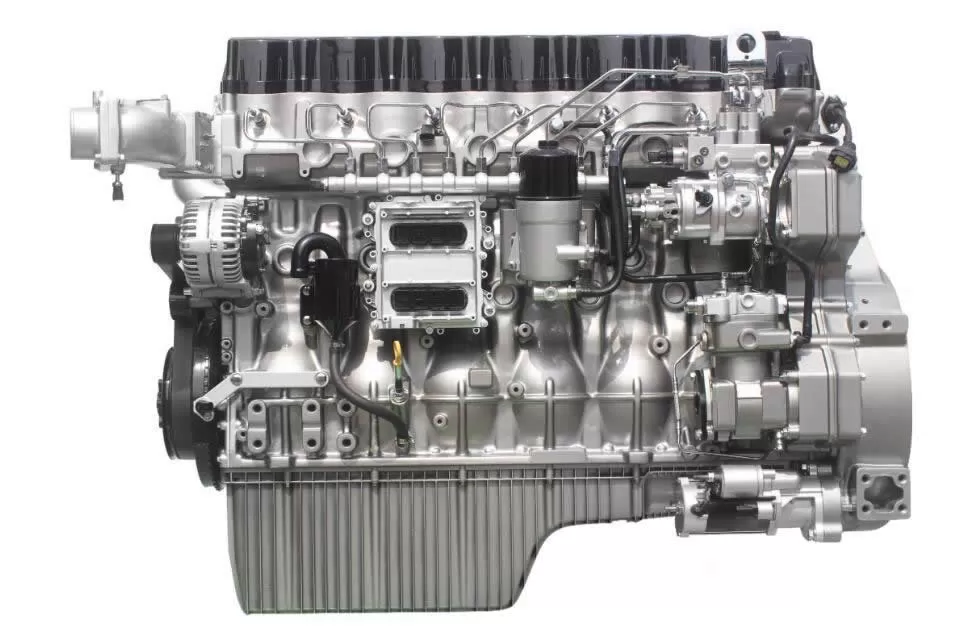

Mining dump trucks are indispensable heavy equipment in modern mining operations. Their efficiency, stability, and operating costs directly determine mining production efficiency. As the core power source of the vehicle, the engine's quality and performance are crucial. Among its numerous engine offerings, the Yuchai K16 series, with its outstanding performance and industry reputation, has become the preferred power solution for mining dump trucks and even large mining vehicles.

Powerful Power

With a displacement of 16 L, peak output of 775 horsepower and maximum torque of 3200 N·m, and approximately 15% increase in low-speed torque, it delivers rapid response and powerful explosive power.

Intelligent Braking Ensures Safety

Equipped with Yuchai's AI intelligent braking system, integrating high-efficiency in-cylinder braking and a hydraulic retarder, it automatically responds to engine and vehicle operating conditions, significantly improving safety during heavy-load downhill driving and reducing the risk of engine overspeeding. The engine's operating time above 2300 rpm is reduced by 76%, and the time between 200 and 2300 rpm is reduced by 49%.

Strong Reliability in Extreme Environments

Verified by high-altitude tests (such as trials in the Changdu mining area at an altitude of 5000 meters), the engine achieves reliable cold starts, low fuel consumption, and stable power in high-altitude conditions.

Engine Parameters

Displacement: 15.5 liters (K16LN gas version) to 16 liters (YCK16 diesel version). The hydrogen-fueled YCK16H has a displacement of 15.93 liters.

Power Range:

Diesel: 580-775 hp (e.g., the mining-grade YCK16 has a maximum of 775 hp);

Gas-fired version (K16LN): Peak power 660 hp, maximum torque 3200 Nm;

Hydrogen-fired version (YCK16H): Maximum 560 hp.

Torque Characteristics: The gas-fired K16LN delivers 2600 Nm at 800 rpm, offering a significant advantage in low-speed high torque.

Technical Highlights

Energy Efficiency: The diesel version offers excellent fuel consumption, delivering 16 liters of power per 13 liters of fuel. The gas-fired version has a minimum fuel consumption of ≤179 g/kWh, 3% lower than competing products.

Reliability: The B10 engine boasts a lifespan of 1.8 million kilometers (same platform technology as the K15N), and its extended oil change design reduces maintenance costs.

Application Scenarios: Primarily mining trucks (such as the Zoomlion ZT115G), gas tractors, and large construction machinery.

Wide supporting and high market recognition

The K16 engine is widely used in the products of companies such as Sany Intelligent Equipment in the field of mining dump trucks. In the industry's promotion of the transformation of mining trucks to large-scale and high-end, the performance of K16 is particularly outstanding.

Supporting new energy transformation

In the field of hybrid, Tongli Heavy Industry's TLDH135 fuel hybrid wide-body dump truck is equipped with Yuchai K16-400 kW range extender system, integrating batteries and 775 horsepower engines, achieving excellent energy-saving performance of 10-15% increase in single vehicle operating efficiency and 10-15% reduction in energy consumption ([cvnews.com.cn][6]).

In order to enhance the professionalism of the column content, the following key points can also be added:

Fuel and emission control

The use of BOSCH high-pressure common rail fuel system, high-efficiency supercharger and optimized combustion technology, combined with low friction design and low accessory loss layout, achieves high fuel efficiency and low emissions.

Longest-Life Structural Design

The engine utilizes a high-strength body and top-down counterflow cooling, eliminating the need for an aftertreatment system. The B10 engine boasts a lifespan of up to 30,000 hours, meeting the high-intensity operation demands of mining operations.

Easy Service and Maintenance

The modular design facilitates maintenance, offering telemetry diagnostics, 500-hour oil and filter change intervals, and the "95098 Excellent Service" network, significantly enhancing user convenience and responsiveness.