As a leading company in China's internal combustion engine industry, Weichai Power's engines are used in a wide range of engineering vehicles in China. By 2024, for example, Weichai's gas-fired heavy-duty truck engine market share is projected to reach 60%. The launch of its all-new gas-powered WP16NG4.0 product is leading a new revolution in the industry. The currently released Weichai Power 445 platform permanent magnet synchronous motor technology offers more reliable, efficient, and intelligent features, including multi-functionality, enhanced efficiency, robust protection, and intelligent matching. It also provides a groundbreaking solution for extended-range mining truck powertrains. Below, we will analyze the Weichai Power 445 platform permanent magnet synchronous motor technology.

Currently, mining trucks face three core challenges:

High energy consumption: Traditional diesel powertrains consume up to 80L/100km under heavy-load climbing conditions;

Emission restrictions: Closed mining environments have stringent NOx/PM emissions requirements (must meet the National IV non-road standard);

Range anxiety: Pure electric mining trucks face a bottleneck during continuous operation due to a lack of charging stations.

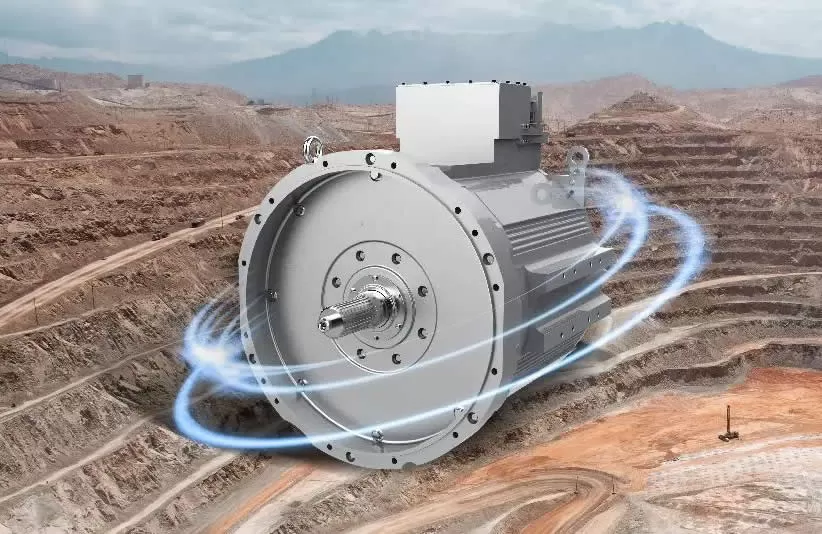

Weichai Power's 445 platform permanent magnet synchronous motor (peak power 445kW, maximum torque 2800N·m) utilizes an innovative range-extended technology architecture to achieve:

A 38% reduction in overall energy consumption (measured data);

Over 60% reduction in exhaust emissions;

A range exceeding 500km (diesel engine + power battery operating in synergistic mode).

Dual-Mode Cooling System

A hybrid oil and water cooling solution keeps the motor's operating temperature below 85°C.

Overload capacity is 15% higher than the industry average.

Intelligent Energy Management

Adaptive control algorithm based on operating conditions (Patent No. CN2024102*****).

Enables:

Kinetic energy recovery efficiency ≥ 92% on downhill sections;

Optimal power allocation between the diesel engine and the electric motor under heavy loads.

Modular Design

Highly integrated motor controller and drive motor (23% volume reduction);

Supports rapid replacement and repair (MTTR < 2 hours).

An open-pit coal mine project in Inner Mongolia (Q2 2025 data):

|

index |

Traditional mining cards |

445 platform extended-range mining truck |

Improvement |

|

Transport cost per ton |

¥ 6.8 |

¥ 4.2 |

↓38.2% |

|

Average daily attendance rate |

78% |

93% |

↑19.2% |

|

Noise level |

89dB |

72dB |

↓19.1% |

The China Construction Machinery Industry Association predicts that by 2026, extended-range mining trucks will account for 45% of the new energy mining truck market. Weichai's technology offers three key benefits:

Laying the foundation for electric drive for hydrogen fuel cell mining trucks;

Promoting zero-carbon mining operations;

Reshaping the TCO (total cost of ownership) calculation model for mining vehicles.