In the hot summer, the heat wave is sweeping in. The hydraulic components of engineering vehicles are facing severe tests brought by high temperatures, such as decreased oil viscosity, accelerated aging of seals, and increased risk of leakage. Chongqing Wendy Vehicles provides a detailed introduction to hydraulic maintenance for engineering vehicles.

High temperature environment will lead to:

Decrease in hydraulic oil viscosity and deterioration of lubricity;

Accelerated aging of seals, hardening and even cracking;

Significantly increased risk of leakage;

The system is prone to overheating and oil temperature is out of control.

(1) Choose suitable grease and hydraulic oil

Use 2# and above grease to improve lubrication effect.

According to the equipment instructions, choose high viscosity index (VI) hydraulic oil or low viscosity oil, such as A, to cope with high temperature viscosity fluctuations.

Ensure that the oil is clean, free of emulsification and moisture, and the oil level is normal; replace and replenish in time if contaminated.

(2) Install monitoring and heat dissipation accessories

Install an oil temperature gauge/sensor to monitor in real time whether the oil temperature exceeds the safe range of 65°C.

Add an oil cooler, fan or increase the heat dissipation area to prevent overheating.

(1) Regular cleaning and anti-corrosion treatment

Keep the surface of the cylinder and piston rod clean: wipe off oil and dust, and remove early rust.

Regularly remove rust and repaint the exposed parts to prevent moisture and corrosion.

(2) Seal inspection and preventive replacement

Pay attention to bulging and corrosion of the piston rod coating;

Check the soft hardening and deformation of the seal ring and dust ring; it is recommended to prevent the replacement of older equipment.

(3) Control load and temperature

Avoid overload operation to reduce damage to the piston, rod and seal.

The hydraulic oil temperature should be controlled between 5°C and 65°C.

(1) Replace high VI or multi-grade oil

Use high viscosity index oil to ensure stable viscosity under temperature difference.

Multi-grade oil should increase 30% viscosity margin in advance in hot environment.

(2) Enhance oil filtration and analysis

Regularly check and replace filter elements (7–15µm);

Establish an oil sample analysis system to detect moisture, bubbles, and foaming.

(3) Strengthen cooling system maintenance

Clean the cooler and oil tank cooling components to keep them unobstructed.

Use a dry and ventilated environment in closed and high-humidity places to prevent condensation.

(4) Prevent cavitation and cavitation

Maintain the oil level in the oil tank to avoid inhaling air;

Flush or replace aging hoses and hoses to prevent cavitation and air infiltration.

(5) Operation and training system

Develop a seasonal inspection checklist: oil temperature, leakage, sound, temperature rise, and oil condition.

Strengthen operator training, familiarize yourself with high-temperature maintenance techniques, and avoid equipment abuse or ignoring warnings.

|

question |

reason |

Countermeasures |

|

Abnormal noise (impact/cavitation sound) |

Air bubbles mixed in, oil temperature is too high, viscosity is too low |

Exhaust, cool down, use high VI oil |

|

Piston rod scratches/oil leakage |

Dust enters, seals are damaged |

Dust removal, rod protection, seal replacement |

|

Abnormally high temperature |

Filter blockage, cooling failure, overload |

Clean, replace filter element, reduce load |

|

leakage |

Aging of seals, wrong installation, abnormal pressure |

Disassembly, inspection, parts replacement, pressure setting |

|

Cylinder deformation or breakdown |

Installation misalignment, overload, material mismatch |

Redo installation, correct alignment and load |

(1) Seal selection: It is recommended to use high-temperature resistant materials in summer, such as Viton and PTFE composite seals.

(2) High-temperature oil quality management: The temperature rises quickly in summer, and the oil quality oxidizes and foams seriously. It is recommended to shorten the oil change cycle and monitoring frequency.

|

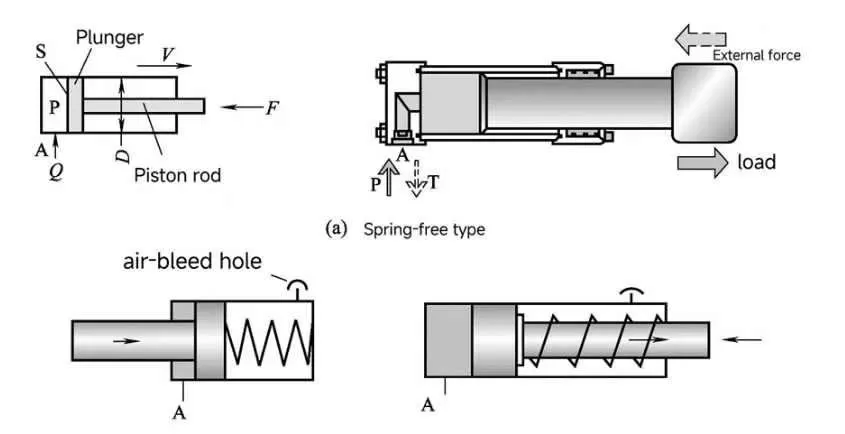

Pictured parts |

Main structure |

Summer maintenance focus |

|

Cylinder head and cylinder barrel |

Sealing surface, mounting bolts |

After cleaning, check whether it is loose; if the rubber ring is aged, deformed or cracked, it should be replaced |

|

Guide bushing (inside the cylinder head shown in the diagram) |

Piston rod guide |

Lubricate regularly to maintain the fit clearance and reduce lateral wear |

|

Piston and piston rod |

Piston seal installation area |

Check whether the coating on the piston rod surface is intact and whether there is any corrosion, bulge or scratch; if the seals (such as U-rings, dust seals) are hardened or "seized", they should be replaced in time. |

|

Inside the cylinder |

Sliding surface and oil channel |

Apply butter or lubricate with hydraulic oil regularly to prevent abnormal noise caused by dry friction. In summer, it is recommended to apply 2# or above butter to enhance lubrication protection. |

|

Oil flow channel |

Oil inlet/air vent |

In summer, high VI value hydraulic oil should be used, or oil should be selected according to equipment requirements; ensure that the oil temperature is below 65°C, and avoid oil emulsification, water or impurities; if the oil is found to be discolored or turbid, it should be replaced or replenished in time |

Through a structured summer maintenance strategy, including the reasonable selection of oil, seals, cooling and monitoring accessories, combined with regular cleaning, inspection, replacement, training and oil analysis, the stability and life of the hydraulic system of engineering vehicles can be significantly improved, ensuring safe and reliable operation in high-temperature environments.