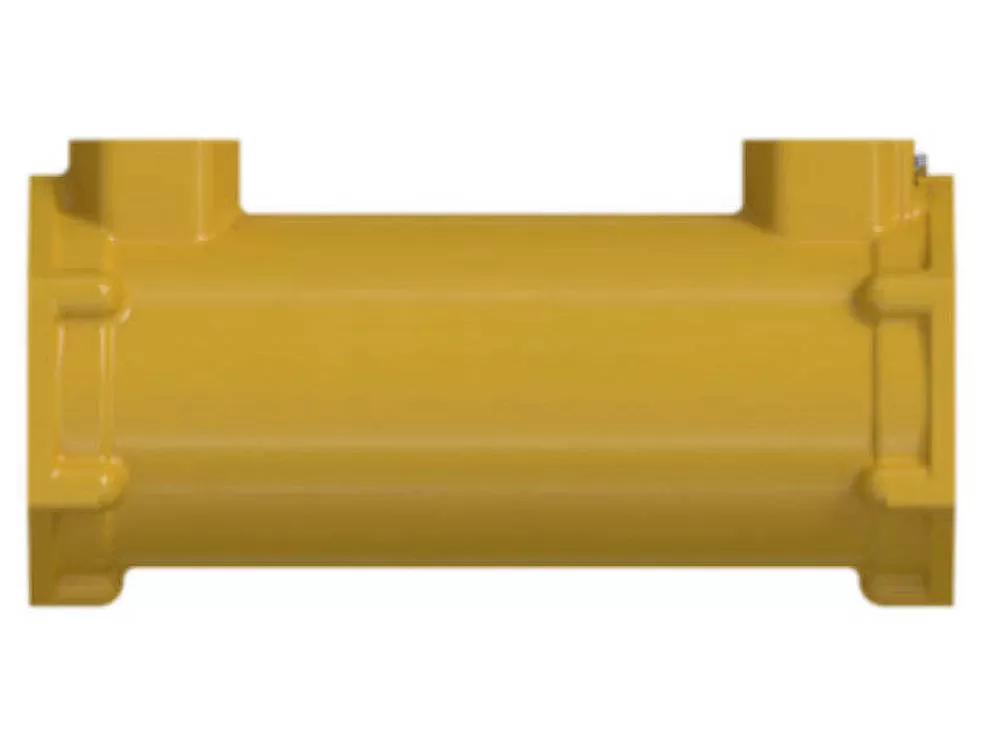

Oil cooler core part number 4W9822 0R5549 for engines C-12, C-10, C11, C13, C15, 3176C, 3196, and C18

An oil cooler is a crucial device for reducing the operating temperature of an internal combustion engine and extending the life of the lubricating oil. It transfers heat generated by the engine to a cooling medium (usually air or water) through the principle of cooling heat transfer, thereby maintaining the oil and engine within a suitable operating temperature range. High-performance, high-power engines, due to their high heat load, require the installation of an oil cooler.

The oil cooler is located in the circulating oil circuit of the lubrication system, and its working principle is the same as that of a radiator. If the oil cooler is damaged, it will cause the engine oil to remain at a high temperature, and the system will issue an overheating alarm. This will prevent the oil from effectively lubricating the engine interior, accelerating wear, shortening engine life, and in severe cases, even causing engine damage.

Features of Bulldozer Oil Coolers

As heavy construction machinery, bulldozers have high engine power and heavy workloads, making oil coolers particularly important. Bulldozer oil coolers typically employ a water-cooled pipe design, mounted on the right side of the engine block, with copper tubing for the water supply. Their main functions are to prevent engine overheating, reduce oil aging, and improve the lubricating performance of the oil.

|

brand

|

SHANTUI

|

|

Warranty period

|

No after-sales service

|

|

Mechanical test report

|

Unavailable

|

|

quality

|

High quality

|

|

country of origin

|

Shandong, China

|

|

Video factory inspection

|

Unavailable

|

|

Warranty period

|

No after-sales service

|

|

size

|

300*250 * 250mm

|

|

app

|

Engines: C-12, C-10, C11, C13, C15, 3176C, 3196, C18

|

|

Part Number

|

0R5549 4W9822

|

|

Part Name

|

Heat from the oil is dissipated through the coil.

|