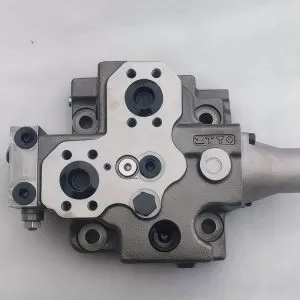

Fule filters for excavators PC200, PC220, PC300, PC300HD, PC350, and PC360: 6003119121, 600-311-9121, 6003118320, 600-311-8320

Filters are key devices in hydraulic systems used to intercept contaminant particles in the hydraulic fluid. They consist of a filter element and a housing, effectively filtering mechanical impurities, metal powder, and colloidal contaminants, protecting hydraulic components from wear. Their core function is maintaining fluid cleanliness. Statistics show that approximately 70% of hydraulic system failures are caused by fluid contamination; therefore, filters are crucial to equipment reliability and lifespan.

Main Types and Features

By Filtration Accuracy: Divided into coarse filters (>100μm), medium filters (10-100μm), and fine filters (1-10μm).

By Structural Form: Includes mesh filters, wire-gap filters, paper core filters, sintered filters, and magnetic filters, etc.

By installation location: Common types include suction filters, return filters, and high-pressure filters.

Core Parameters

Filtration accuracy: Refers to the smallest particle size removed (e.g., 5-30μm).

Flow rate: Should be 2-3 times the actual system flow rate to avoid excessive pressure loss.

Operating differential pressure: Typically 0.1-1.6MPa; filter element must be replaced if the differential pressure exceeds this limit.

|

brand

|

OEM

|

|

Warranty period

|

No after-sales service

|

|

Mechanical test report

|

Unavailable

|

|

Part Number

|

600-311-9121 600-311-8320

|

|

Brand Name

|

OEM

|

|

Applicable to

|

Excavator PC200, PC220, PC300, PC300HD

|

|

quality

|

High quality

|

|

country of origin

|

Shandong, China

|

|

Video factory inspection

|

Unavailable

|

|

Product Name

|

6003119121

6003118320

|

|

Part Name

|

Fule Filter

|

|

app

|

Construction machinery engine

|

|

brand

|

OEM

|

|

Warranty period

|

No after-sales service

|