Diesel forklifts, as common internal combustion material handling equipment, are core equipment in the industrial logistics field. Their performance stability directly affects operational efficiency and safety, and they possess advantages such as high load capacity and good adaptability to harsh environments. However, the workload and environmental pollution they endure in different operating scenarios (indoor and outdoor) vary greatly. The operating environments differ significantly between indoor and outdoor conditions. Outdoor operations face challenges such as dust, temperature and humidity fluctuations, and bumpy roads, while indoor operations require attention to space limitations and air quality impacts. Scientific maintenance not only extends equipment lifespan but also effectively prevents sudden failures and reduces overall operating costs. Post-operation maintenance is particularly crucial: it's an important window for removing accumulated dust, checking for leaks, replenishing lubrication, and preventing corrosion and fatigue damage. Proper maintenance can effectively extend component lifespan, improve operating efficiency and safety, and reduce downtime. The following is a detailed technical analysis of the key maintenance points for diesel forklifts after indoor and outdoor operations.

Before performing specific maintenance on a diesel forklift, several general principles should be followed:

1.1 Safety First: Before maintenance, the forklift must be parked on level ground, the engine completely turned off, the handbrake engaged, the key removed, and all other power sources disconnected.

1.2 Cleaning First: Removing dirt, dust, and oil is fundamental for subsequent inspection and lubrication.

1.3 Check Seals and Tightness: All connections, bolts, and pipes may loosen, leak, or become fatigued due to vibration.

1.4 Fluid Maintenance: Check and replenish engine oil, hydraulic oil, coolant, brake fluid, etc., ensuring the fluid levels are within the appropriate range.

1.5 Record Maintenance: It is recommended to keep a maintenance record for each service to facilitate tracking of equipment status and future diagnostics.

Indoor operations (such as warehouses and factory workshops) typically involve less dust and have smoother floors, but the following maintenance points still apply:

2.1 Surface Cleaning

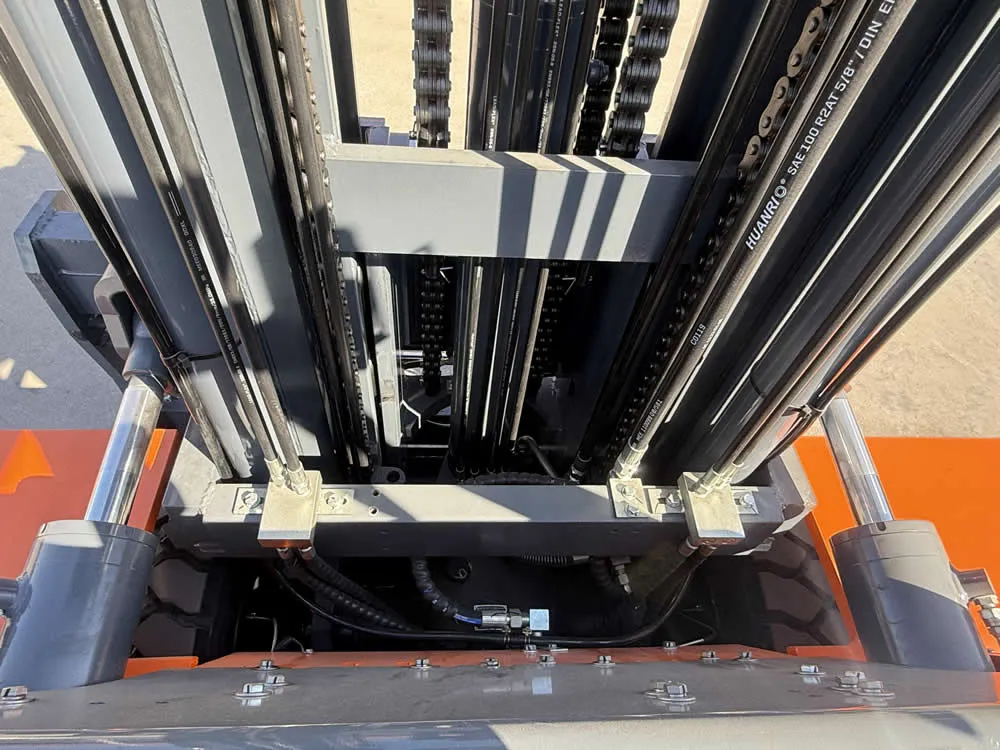

For indoor operations, pay attention to cleaning dust from the cab interior. Use soft water or specialized cleaning equipment to wash the vehicle body, focusing on areas prone to dust accumulation such as the fork carriage, mast tracks, and battery terminals. The recommended washing pressure is 0.2-0.4 MPa.

Use a brush or compressed air to remove dust from the forks, mast tracks, and undercarriage.

Clean the engine compartment (where dust may enter but is less than outdoors), air filter, and radiator exterior.

2.2 Fluid Level Check

Check the levels of engine oil, hydraulic oil, coolant, and brake fluid.

If the fluid levels are low, top up as needed.

2.3 Fastener Inspection

Check the fork carriage support bolts, wheel bolts, chain tension bolts, and steering and braking system bolts for looseness.

System Inspection, Check for loose connections such as the fork carriage support, lifting chain tension bolts, and wheel retaining pins.

2.4 Leak Detection

Inspect pipelines, joints, oil tank, oil pan, and hydraulic cylinders for oil leaks.

2.5 Brakes and Safety Devices

Check the brake pedal for smooth operation and any abnormal sticking.

Check the horn, lights, and instruments for proper function.

2.6 Lubrication

Inject grease into the mast support and tilt cylinder pivot points until new grease seeps out.

2.7 Engine Inspection

Start the engine and check for smooth operation, unusual noises, and the responsiveness of the hydraulic system (lifting and tilting).

Outdoor operations (such as construction sites and open storage yards) pose a more severe challenge to forklifts. Due to factors such as mud, water, dust, and changes in ambient temperature, the focus of maintenance will differ.

3.1 Thorough Cleaning

Use a high-pressure water gun (moderate pressure) to wash the chassis, tires, and frame to remove mud and water.

High-pressure washing of the chassis (1.8-2.5 MPa) is essential to prevent corrosive residue.

Caution: Do not spray water directly into electrical contacts to avoid damaging sensitive components.

Clean the radiator and cooler ports to prevent dust/mud blockage that could impair heat dissipation.

3.2 Moisture Control

Check the cooling system for moisture. Consider draining moisture before a cold start (if the temperature is low).

Drain any potential moisture in the fuel system (especially water in diesel fuel) using a separator.

3.3 Maintenance of Pipelines and Seals

Outdoor dust and moisture can easily enter pipe joints. Check seals (such as O-rings) for aging or leaks.

Due to bumpy roads, bolts can easily loosen. Increase the frequency of retightening brake and steering gear bolts.

3.4 Tire and Suspension Inspection

Inspect tires for embedded stones, cuts, or damage.

Check tire pressure to ensure it is normal, as pressure may vary due to outdoor temperature fluctuations.

3.5 Cooling System Maintenance

After washing the radiator exterior, check the fan belt tension and condition.

Check the thermostat and coolant level to ensure cooling efficiency.

3.6 Lubrication and Rust Protection

Apply grease to the mast, hinges, and other joints.

Perform rust and corrosion prevention treatment on exposed metal parts (such as fork arms and frame), especially for equipment operating outdoors for extended periods.

3.7 Leaks and Pressure Relief

Inspect all hydraulic cylinders and lines for leaks or damage.

If oil leaks are found, repair or replace seals promptly.

In addition to daily or post-shift maintenance, periodic technical care is essential:

4.1 Maintenance Cycle Recommendations

Develop a technical maintenance plan based on forklift usage time and hours. Many forklift manufacturers recommend Level 1, Level 2, and Level 3 maintenance.

For example, some sources indicate that certain internal combustion forklifts should undergo their first maintenance after approximately 150 hours of operation, followed by Level 1 maintenance based on usage frequency (e.g., every 350 hours).

4.2 Technical Maintenance Contents

Change engine oil, diesel filter, and air filter.

Check and adjust valve clearance.

Check the hydraulic system (multi-way valve, lifting cylinder, tilting cylinder, gear pump, etc.) for proper operation. Verify the smooth operation of actuators such as the multi-way directional valve and lifting cylinder.

Adjust the clearance between the foot brake and handbrake.

Check the secure installation of the alternator/starter, wiring connections, and electrical system. Check cylinder pressure and valve clearance, and adjust to the standard range.

Check the fan belt tension. Check the smoothness of gear shifting; replace the oil filter and diesel filter element. Check the condition and tension of the lifting chain and links.

4.3 Major Inspections

A comprehensive overhaul should be performed every extended period (several hundred hours or years): Inspect the transmission system (gearbox, differential), hydraulic pump/cylinder seals, final drive, etc.

Clean or replace worn seals, gaskets, O-rings, etc.

Clean the diesel pre-filter water cup and purge air from low-pressure lines using a manual fuel pump. Precision components such as the fuel injection pump must have their fuel supply and injection angle calibrated by a professional on a test bench.

4.4 Records and Prevention

Establish maintenance records, documenting each maintenance item, hour, problem found, and handling method.

Develop preventative maintenance plans based on historical maintenance records and failure trends to reduce unexpected breakdowns.

5.1 Training and Responsibility Division

Operators should receive basic maintenance training (such as daily inspection, cleaning, and simple lubrication).

Professional maintenance personnel (technicians) are responsible for periodic technical maintenance and major overhauls.

5.2 Environmental Adaptability Adjustment

For forklifts operating in harsh outdoor environments (high dust, humidity, extreme temperatures) for extended periods, consider enhanced protective measures, such as regular use of dust covers and periodic rust inhibitor spraying.

In low-temperature environments, prevent cold-start damage (e.g., check coolant, antifreeze, preheat equipment, etc.).

5.3 Safety and Compliance

Strictly follow pre-maintenance safety procedures (power off, handbrake engaged, key removed, etc.), and never omit safety steps.

Maintenance records should comply with company policies or regulatory requirements to ensure accountability.

5.4 Parts and Lubricant Selection

Using manufacturer-recommended or high-quality filters, greases, and hydraulic oils can extend equipment life.

For older equipment, regularly assess whether critical seals or components need replacement.

Post-operation maintenance is crucial: Whether operating indoors or outdoors, timely cleaning, inspection, and lubrication are fundamental to preventing premature equipment damage, reducing the risk of failure, and maintaining stable performance. Establishing a systematic diesel forklift maintenance system requires developing differentiated plans based on the characteristics of indoor and outdoor operations. By adhering to standardized daily maintenance, timely periodic maintenance, and flexibility in environmental adaptation, equipment efficiency can be significantly improved, achieving both safety and economic benefits.

Periodic technical maintenance is indispensable: Combining daily inspections with regular technical maintenance maximizes forklift lifespan and reliability.

Ensuring implementation through systems and training: Establishing maintenance systems, training operators and maintenance personnel, and maintaining records and reviews are crucial for long-term stable operation.